Deep Boiling Process

This is the most commonly used process by our customers.

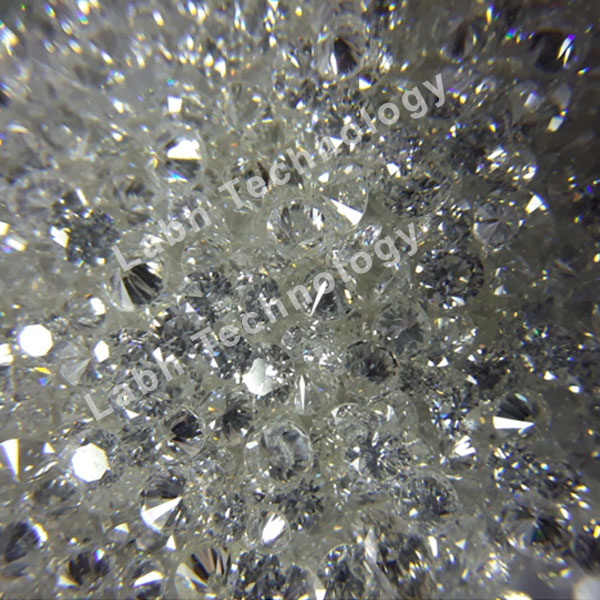

We recommend this process for each and every diamond as it results in higher light reflection which in turn causes the diamond to give out immense light and lustre.

It removes dirt and trace materials from Lb, tlb, lc and white thus allowing diamonds to reach their highest potential value. Deep boiling diamonds is a process, deep boiling.

Whose aim is to remove, distance, metabolize and whiten dark stains that are found in the stones and which have access to an external facet.

His purpose of deep boiling is to try and reach internal dirt, which the boiling materials can reach via a tiny crack known as an “open inclusion” the tiny bit of black graphite trapped inside the diamond. These tiny dots are trapped in the diamond when it is formed. The process allows dirt to be removed so the polished diamond looks better.

Advantages :

- Unlike normal boiling, the diamond is processed inside an electric regulated furnace under the influence of various chemicals which eventually results in brighter diamonds.

DIFFERENT TYPES OF DIAMOIND BOILING CAN BE DONE IN THIS PROCESS AS FOLLOWS

- STAR MELEES = like WHITE , LB, LC ETC which improve the luster of diamonds and brightnes.

- GIA CERTIFIED DIAMOND (SINGLE POINTER)= 0.30ct, 0.50 , 1.00ct, 1.50ct, 2.00ct ……5ct, 10ct, 15ct,20ct…. etc which improve light luster and brightness.

- ROUGH DIAMOND = All size and quality of rough diamond we can boil like catoca , angola, Zimbabwe, pk grey natts, Russian, lb , diavik, argyle etc which remove dirts trace materials from diamond and clean it properly.

- In this boiling process all types industrial goods,cvd rough diamonds, polki, chakri etc can be done.

FREE SAMPLE PROVISION – AS PER RULES AND REGULATION OF COMPANY