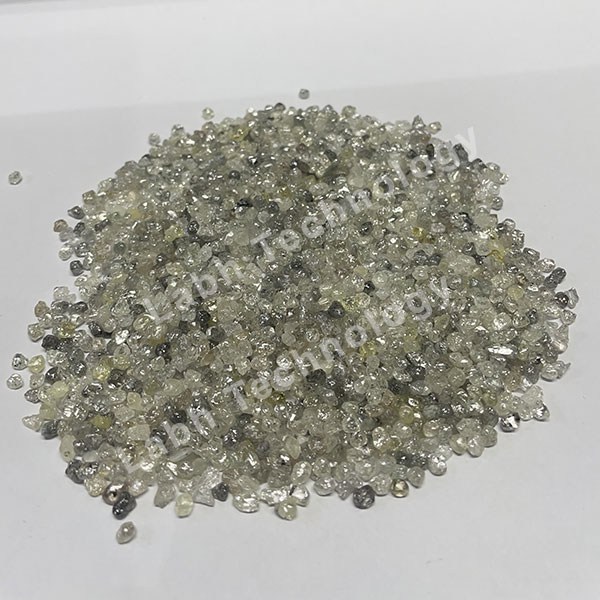

Rough Diamond Boiling Process

The rough diamonds are freed from various impurities and hence a better quality of polished diamond could be manufactured out of the same rough sample. In order to clean these impurities from within the rough diamond, the stone must be subjected to vaporized gases, which can get inside these microscopic cracks to do their work. The long-standing method of achieving this gas vaporization is a multi-stage process. There are many different variations of this process, and our cleaning process maintain unique ‘recipe’ of chemicals and processes. At the core of the process is the mixture of chemicals in an autoclave. These chemicals usually consist of mixed ratios of different types of chemicals and these chemicals are boiled at 250-500°C. This boiling vaporizes the acids, which expand and build up pressure within the sealed autoclave. This pressure forces the gases into the cracks of the stones, where they digest the organic materials within.

Advantages :

- Rough diamond gets cleans internally and results in a better quality of polished diamond.

- This process also helps in removing the blackishness caused due to sawing.

- And also the face value of the diamond rough is increased in the market due to this process.

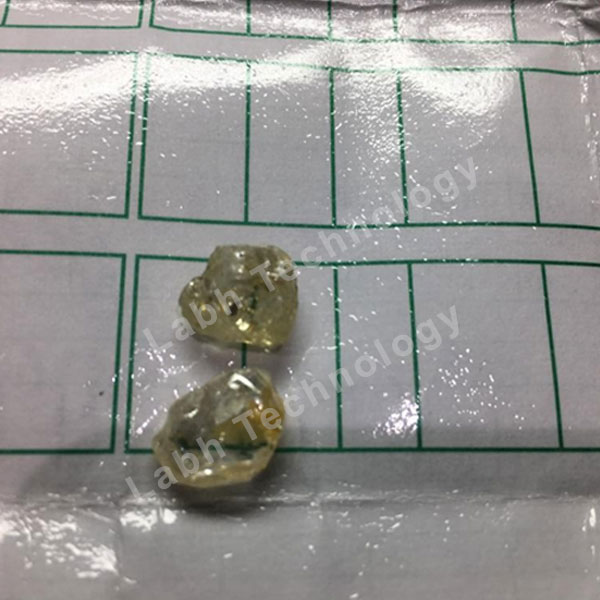

Before

After

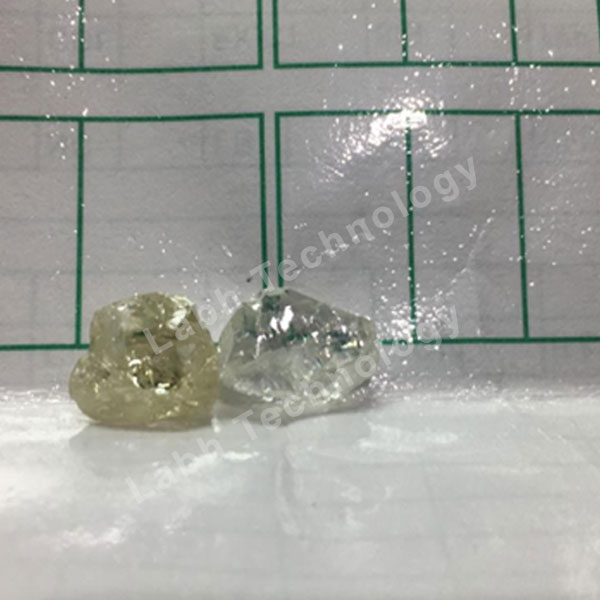

Before

After

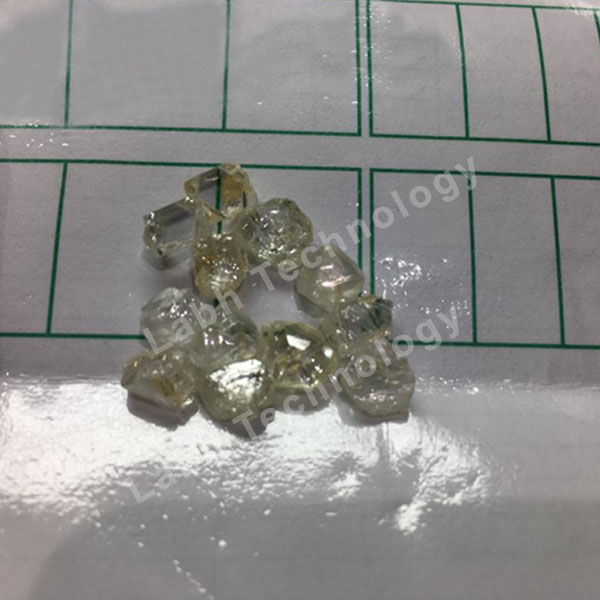

Before

After

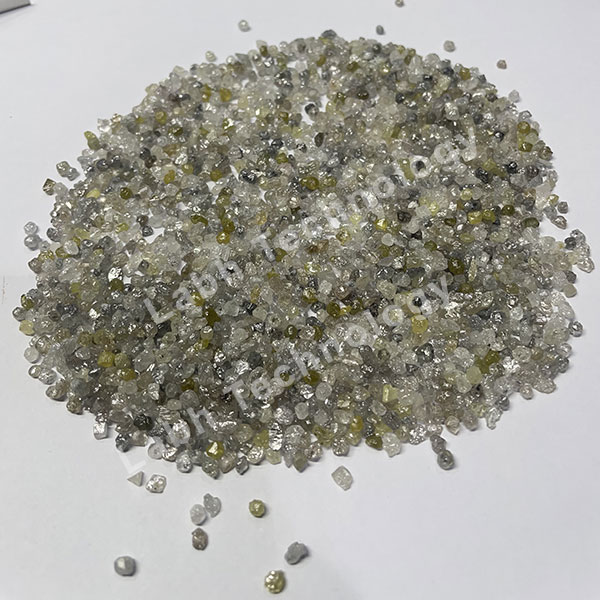

Before

After

Before

After

Before

After

Before

After

Before

After

Before

After

Before

After

Before

After

Before